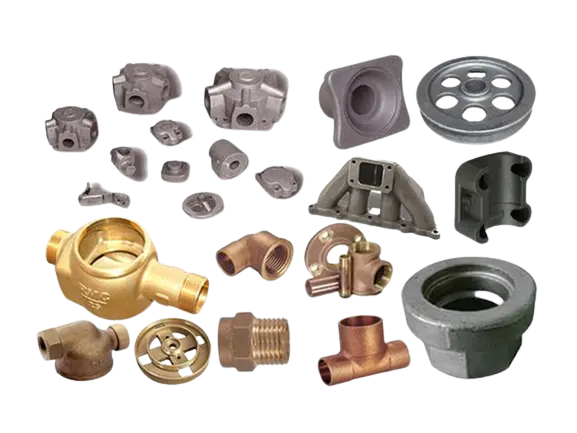

Casting

Forfront is your reliable Partner for Sourcing & Manufacturing all your Cast Components from India. These parts can be supplied as Raw or Fully Machined or with multitude surface treatments. We will also ensure that the finished parts are dispatched on-time through keen follow-up at every stage, through in-process & quality control and final inspection.

Our manufacturing partners are adhering to Stringent Quality norms and with all required Quality Accreditations like ISO 9001:2015 and IATF - 16949 systems or any other required certifications. When it comes to Material grades, our Castings conform to several International standards such as ISO, BS, ASTM, ASME, ANSI, DIN, JIS, etc.,

Casting Processes

Sand Castings

Cast Iron, Ductile/SG iron, Carbon & Alloy Steel, Stainless Steel, Nickel Steels and Non-Ferrous.

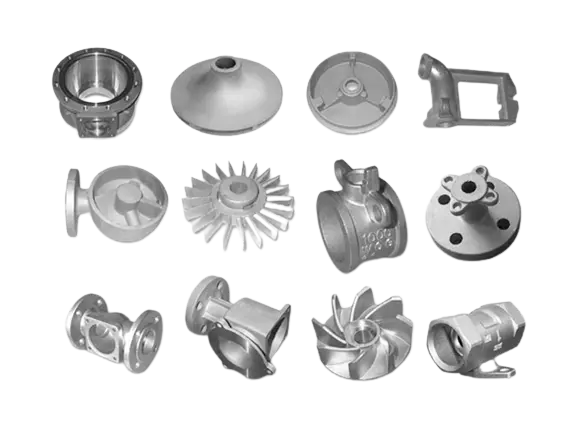

Investment Castings

Carbon & Alloy Steel, Stainless Steel and Nickel Steels.

Shell Moulding

Cast Iron and Ductile/SG iron.

Gravity Die Castings

Aluminium and Zinc.

Pressure Die Castings (High/Low)

Aluminium and Zinc.

Centrifugal Castings

Carbon & Alloy Steel and Stainless Steel.

Post processing and Surface Treatment

- Special Heat Treatment

- Shot blasting/ Glass beading

- Vacuum Impregnation

- Anodizing

- Special painting & coating

- Various Plating processes.

Third-Part Inspection Services

- Mechanical – Hardness/ Impact/ Tensile/ YS

- Metallurgical – Chemical/ Microstructure

- Vacuum Impregnation

- Anodizing

- Special painting & coating

- Non-Destructive – MPT/ DPT/ UT/ RT.

Sand castings

Shell Moulding

Investment Castings